PENTAFLEX 16 Links can be found on the main Mishkin Productions site, HERE

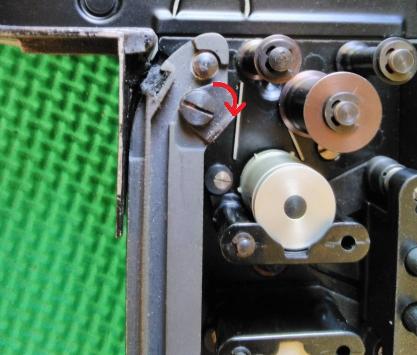

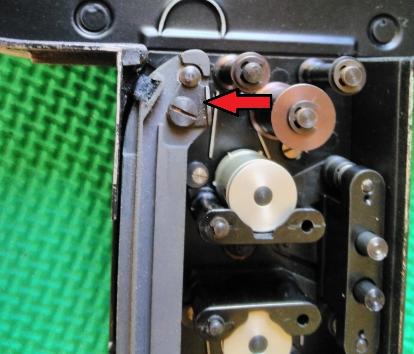

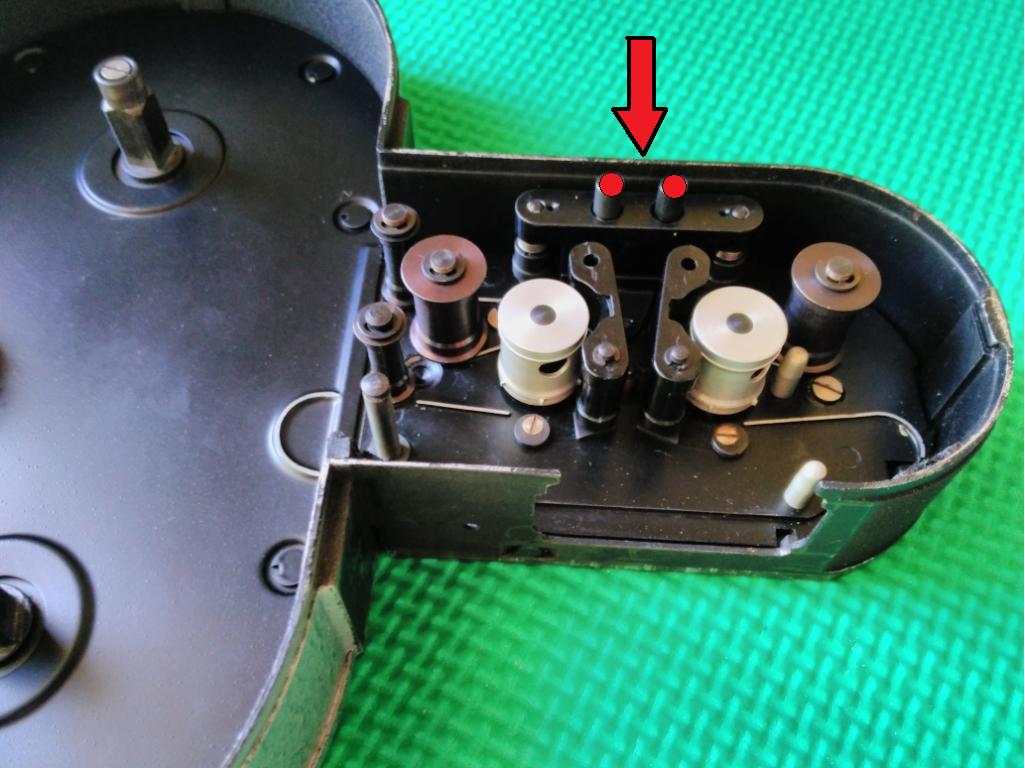

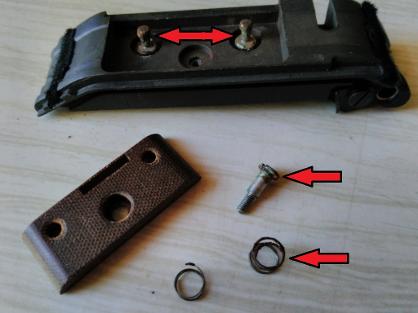

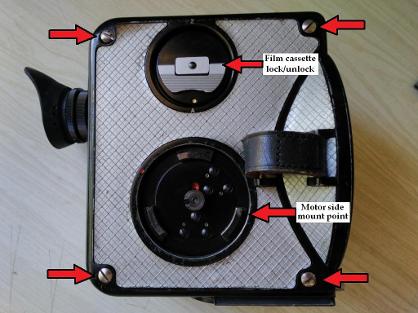

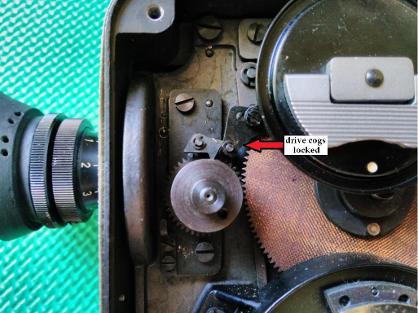

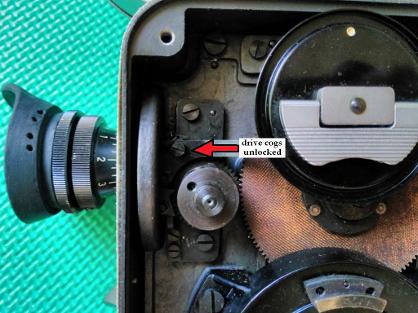

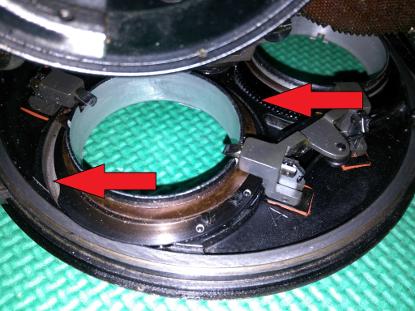

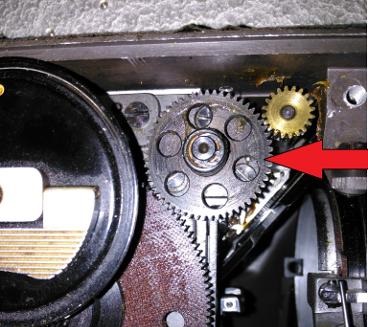

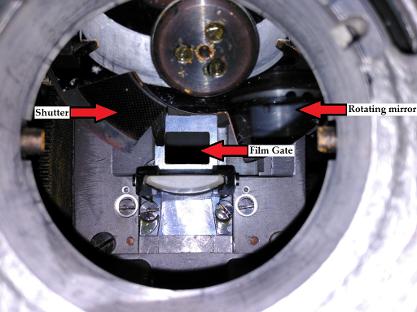

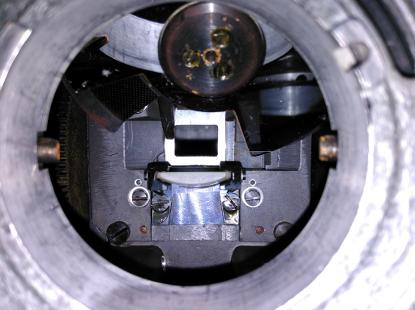

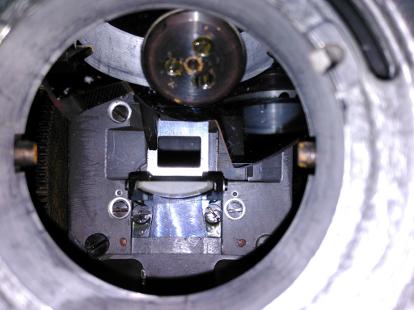

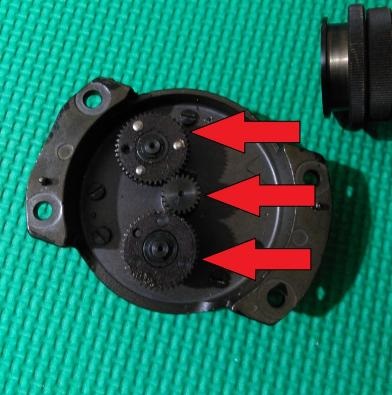

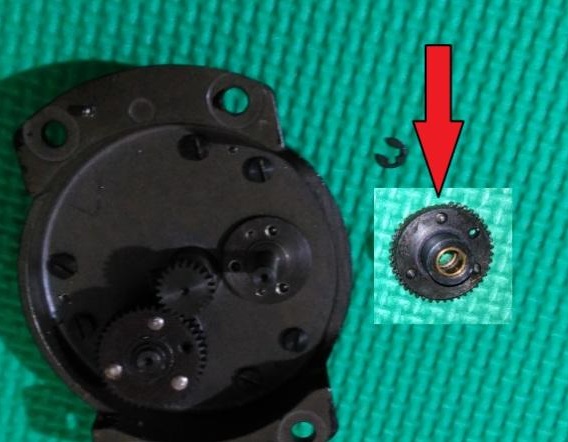

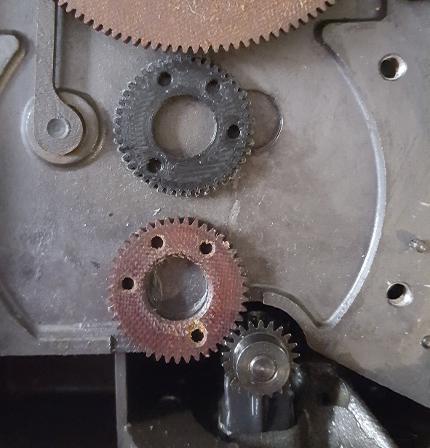

Dismantle: The Pentaflex 16 left side cover can be removed by removing four screws visible on the casing. Once the cover is removed, most of the cogs can be examined. To manually move the cogs by hand, a film cassette has to be inserted into the body, or simply rotate and engage the cassette lock. To test if the motor runs, attach to a 12 volt motorcycle battery.

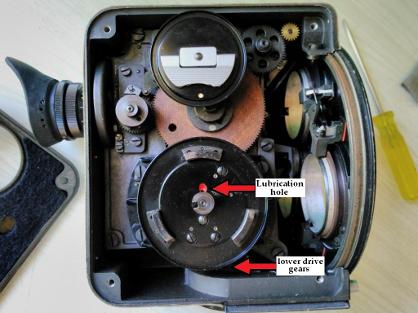

Lubrication: This particular camera, while running, had trouble maintaining a regular speed, fluctuating regardless of the motor speed setting. After opening the casing, and lubricating with “Singer machine” oil, a very light viscosity oil suited for low load and speed applications, the camera was able to maintain what appeared to be very constant speed.

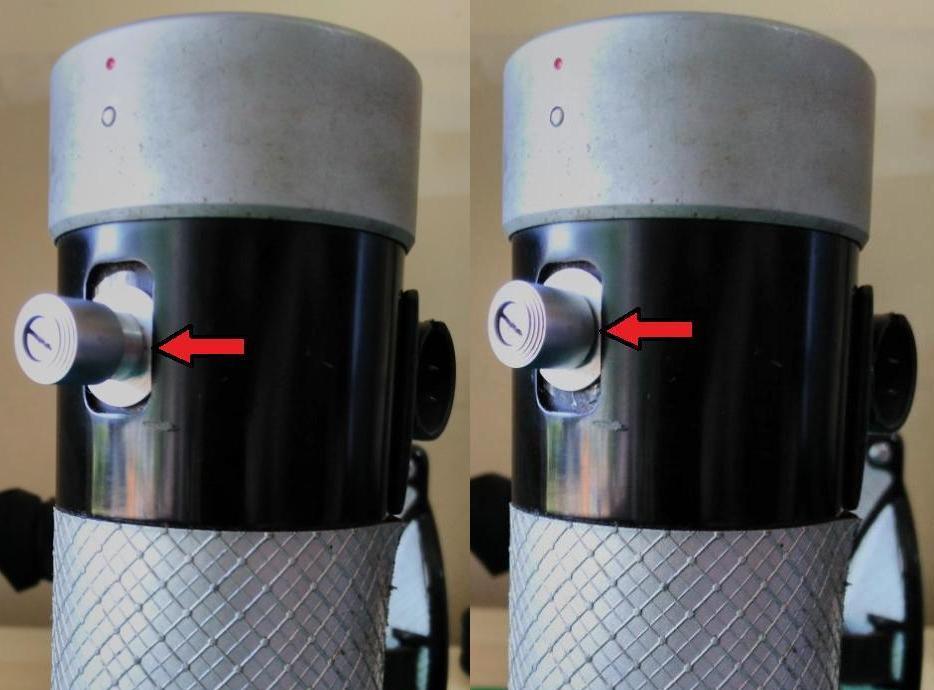

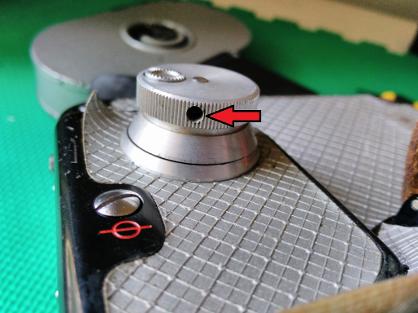

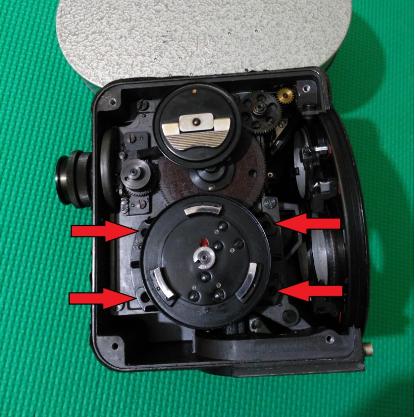

Dry Run Camera: Inserting a loaded film cassette, gently push the cassette into the top of the camera body, through the two "trap doors" on top of the casing. Once the cassette is firmly seated, rotate the winder clockwise until the white dot is at the top, as per below picture, and the cassette moves forward slightly and audibly clicks into place. To remove, simply rotate the winder anti-clockwise until the white dot is at the bottom, as per below picture, and the cassette moves backwards slightly. Pull the cassette out of the camera body.

Note: It is worth noting that this camera has two names. The original VEB factory designated the camera Pentacon AK16. Later, under the DDR, the camera's name was changed to Pentaflex 16. Parts between the two models are interchangeable, and essentially the only differences appear to be cosmetic. Pentacon AK16's are black, Pentaflex 16's are silver coloured.

|

Pentaflex AK16 user manual English translation.pdf Size : 2601.272 Kb Type : pdf |

|

Pentovar lens user manual.output.pdf Size : 168.102 Kb Type : pdf |

|

Pentaflex Spring Motor English translation.pdf Size : 633.98 Kb Type : pdf |

|

Pentaflex 16mm technical data.output.pdf Size : 314.648 Kb Type : pdf |