Mishkin Productions "Using 16mm" page - Many handy links to Bell & Howell cameras

Lubrication: Prospective

D.I.Y lubrication should be researched well, as some cameras have very

specific

requirements, requiring specific oil and/or grease. If you do not know

what is needed, stop until

you know. Do not use automotive

products, or petroleum based greases as some plastic parts may “melt”.

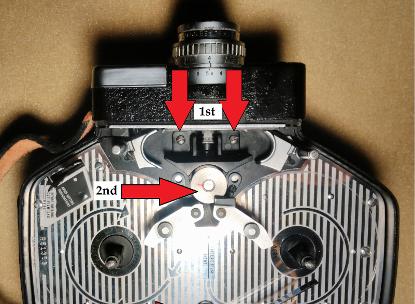

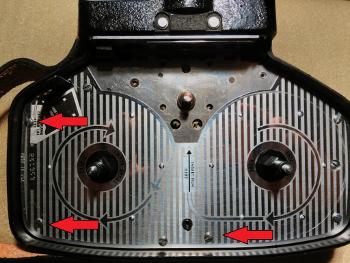

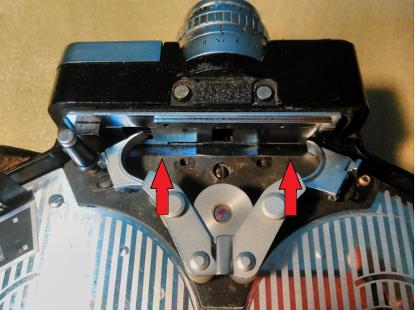

Lubrication of this camera was done using

a “Q” tip, or ear bud dipped in light oil, and gently dabbed where

needed. Excess oil was wiped off. Lubrication should only be used

sparingly on

areas where metal parts rub against each other, such as bearings or worm

gears. Gears that only touch other gears via teeth will not need

lubricant. Plastic gears or moving parts may require

lithium grease, or similar.

Note: As with all equipment such as old cameras, a qualified service person is ideally the first stop when owning a camera. If, however, a person is moderately confident and not heavy handed, basic maintenance will assist in keeping the camera running long enough for you to enjoy using it and then save up money to get it serviced.

CAUTION! When working on a spring winding camera always ensure the spring is run down entirely. Not only is it potentially dangerous to work on anything with a coiled spring inside, the camera motor accidental running a few hundred frames could mess up your marking needed for reassembly.

|

Bell & Howell 240EE user manual.pdf Size : 1486.992 Kb Type : pdf |